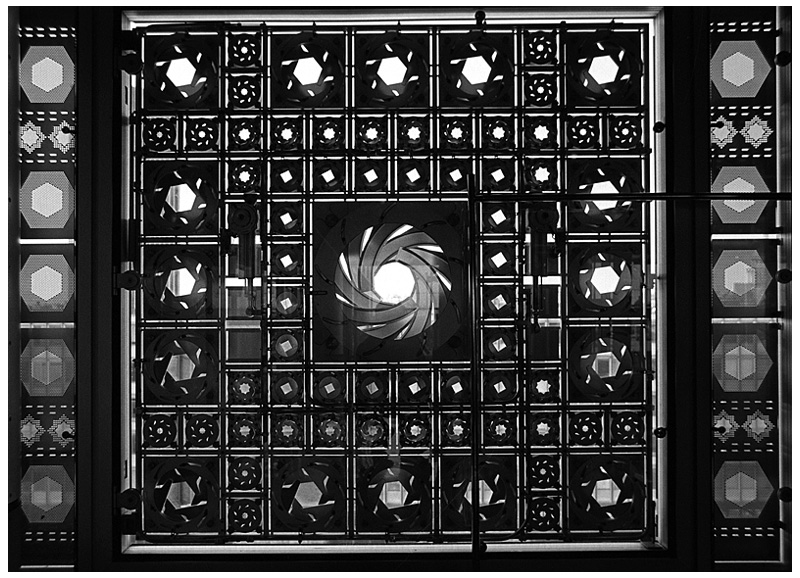

This is a project in which I attempted to create an iris mechanism. I chose it because, besides the aesthetic quality of it, I find its applications very relevant to me. An iris mechanism can be used as an architectural element (as with the mechanical windows at Nouvel’s Arab Institute in Paris shown below), as well as in the context of installations where light and line of sight need to be manipulated somehow.

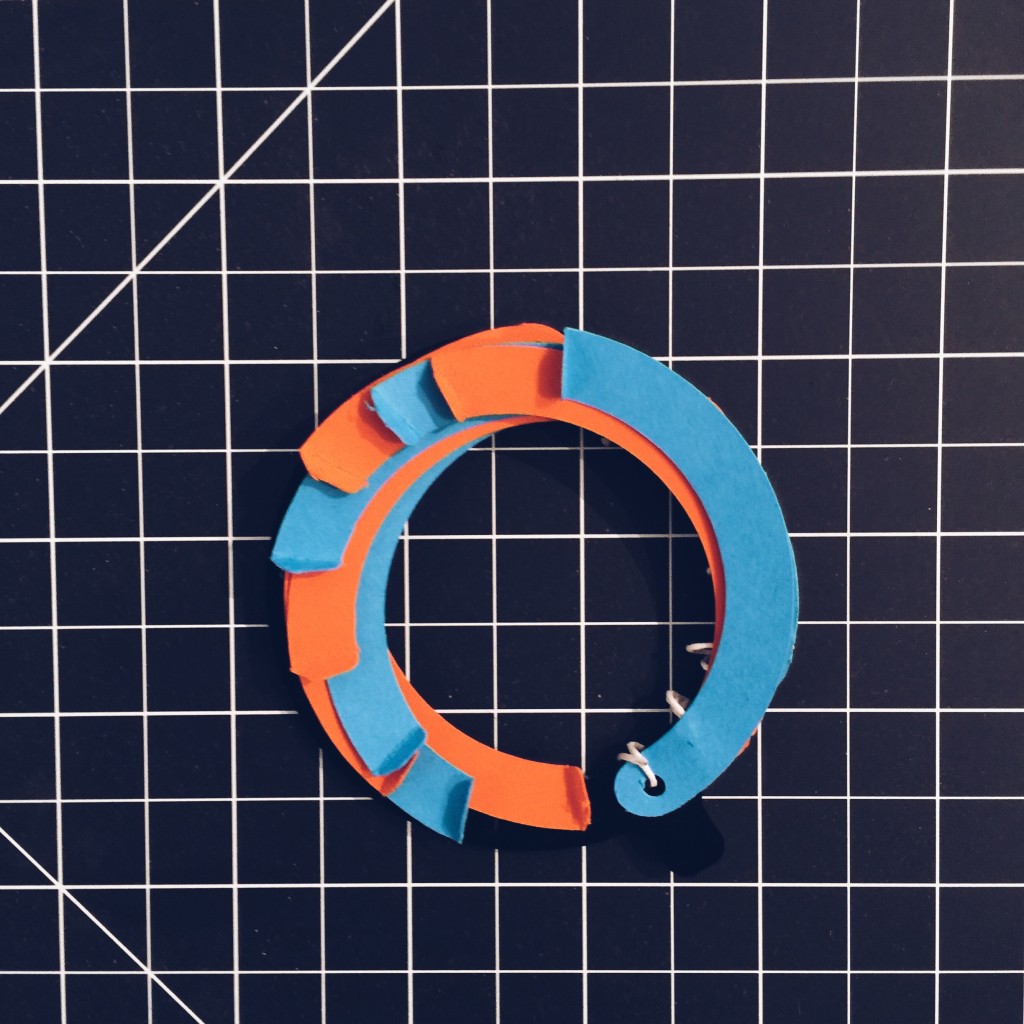

First Prototype

The first prototype I made was to understand the basic structure and the constraints in movement. By following a few guides I read and watched online, I used the vinyl cutter to cut a number of wedges, as well as two different circular parts. The first is what the wedges are attached to. The second has the purpose of constraining a perpendicular part of each wedge so that a simple circular movement provides enough friction for the wedges to open (or close, depending on direction of movement).

The results where aesthetically acceptable, but functionally, the use of cardstock for the two circular parts resulted in an incorrect behavior. The paper material used is not firm enough to hold the pieces in place, nor to provide the required friction for the opening to occur. In addition, I used hemp threads to fasten the wedges into the frame, which is really hard to work with and to make stay in place.

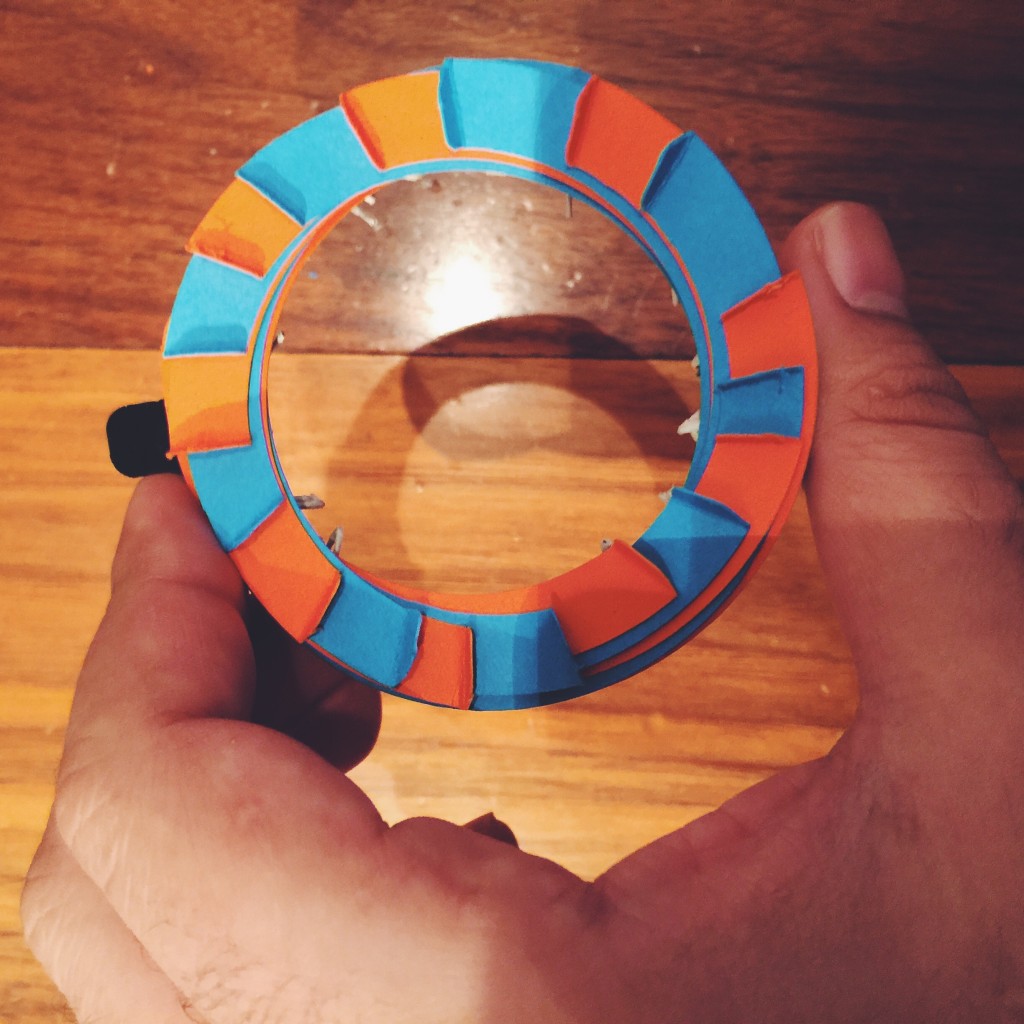

Second Prototype

I attempted to solve the problems with the first prototype by using other materials for both the circular parts, as well as the threads used to keep the wedges in place as a pivot.

I used relatively thin black acrylic for the circular frames, cutting the pieces using the laser-cutter. I also added a third circular frame type to cover the design from above and below.

The process of placing the wedges is time consuming, but the choice of using malleable wires as fasteners (instead of the hemp threads I used in the previous prototype), made the process much smoother.

Using the acrylic, laser-cut “friction” frame, the movement was constrained in the way it is supposed to be.

The final result, as is shown in the image at the top of this post, is functionally quite the improvement over the previous prototype. However, it has its share of problems: the choice of cardstock for the wedges is not strong enough to withstand the force applied by the friction frame. While it worked well initially (the wedges moved appropriately according to the direction of the motion), it soon lost its resistance and the pieces came undone.

Also, there is the visual problem of the visible wire fasteners. The appropriate substitute would be a non-wire like material, that I am yet to identify.

Leave a Reply